Bunded flooring and steel spill decking

Sall’s bunded flooring for spill containment is constructed entirely from galvanized steel. Its modular design allows for seamless adaptation to any industrial surface.

This flexible modular spill deck is purpose-built for maximum strength and durability, even with prolonged and heavy use. It serves as an excellent safeguard for the original flooring while also offering a convenient liquid handling workstation and workspace as well as a safe chemicals storage area.

Additionally, this drive over spill floor bunding not only are a preventative solution able to protect people and the environment from dripping and spill related risks but also significantly improves operational efficiency by allowing forklift transit so that operators can easily transport the chemical containers.

Dimensions of Sall’s drive over sump flooring steel modules

| Art. n. | ECO 14.14 | ECO 19.14 | ECO 29.14 | ECO 29.19 |

|---|---|---|---|---|

| Width x Depth x Height (mm) | 1440 x 1400 x 53 | 1900 x 1400 x 53 | 2900 x 1400 x 53 | 2900 x 1900 x 53 |

| Capacity (L) | 80 | 110 | 170 | 225 |

| Load Capacity (Kg/m²) | 5000 | 5000 | 5000 | 5000 |

| Load Capacity per Wheel (kg) | 2000 | 2000 | 2000 | 2000 |

| Material | Steel | Steel | Steel | Steel |

| Surface Treatment | Galvanisation | Galvanisation | Galvanisation | Galvanisation |

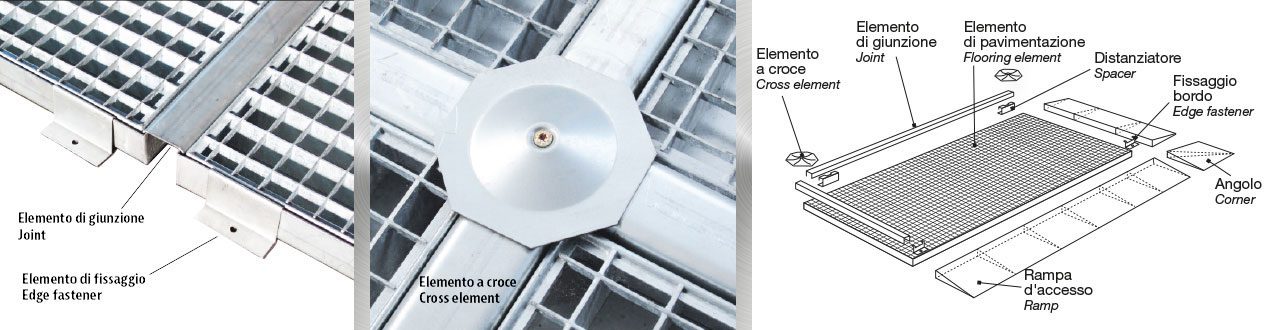

Components of Sall’s modular spill decking system

Sall’s bunded flooring and decking structure

The galvanized steel sump flooring structure coupled with the hot-dip galvanized steel grid withstand extremely heavy loads, so much so that the surface is also safe for the transit of forklifts and pallet jacks.

Transporting and handling primary containers such as drums, tanks, or any other container is easy and secure thanks to the sides equipped with dedicated access ramps.

The certified collection sump, positioned beneath the support surface, is StawaR compliant and watertight tested via non-destructive testing with the use of penetrating liquids, thus ensuring the safe and proper containment of hazardous and polluting liquids.

The high-quality galvanization provides excellent resistance to corrosion and rust, making this modular and drive-over sump flooring the best solution as workstation and additional indoor storage area for most chemicals, flammables and corrosive liquids.

For the acids safe containment is in fact available the interior sump coating made of polyethylene.

Enhance your workspace safety with custom bunded flooring and spill decking!

When it comes to storing acids and highly corrosive liquids, our modular and drive over bunded floor come with an internal polyethylene coating treatment or other suitable plastic materials.

At Sall, we offer indeed the chance of completely customize our bunded flooring systems to meet all your specific requirements and even the most strict Country specific applicable regulation.

Whether you need spill decks for your specific requirements, our experts are here to assist you. Take advantage of our free technical consulting service, request a free quote, or get more information by contacting our dedicated customer service department.

Ensure the maximum protection and prevent costly fines with Sall’s steel bunded flooring solutions. To get started, simply fill out our convenient form or reach out to Sall Experts directly.

Save time, money and experience the peace of mind that comes with reliable spill containment. Contact us today!

Why you should use this bunded flooring system?

- Accessible with forklift trucks and pallet jacks for best operational efficiency.

- Adaptable to any industrial surface thanks to the modular design so that you can easily cover and protect any industrial areas as per your needs.

- Expandable at any time and according to needs so that you save money and you do only have to focus on growing your business.

- Usable both as an indoor storage area and as a safety workspace so that you do not only provide a norms compliant chemicals storage area but also a working station that is compliant with working safety regulations.

- Maximum level of safety and protection for personnel, groundwater, and the environment in case of hazardous liquids dripping, leaks and spills.

- Ideal for compliant storage of flammables, hazardous substances, and pollutants.

- Suitable for acids and highly corrosive liquids thanks to the inner lining of the collection sump in polyethylene or other plastic materials based on the acid type (available upon request).

- Easy cleansing and inspection of the collection tank thanks to the grid design that allows its easy and safe removal.

- Certified and watertight tested sump according to UNI EN ISO 3834:2-2021.

- Easy and quick installation and removal.

- Compliance with EU regulations and most important international regulations for the storage of chemicals, hazardous substances and polluting liquids.

Technical featured of Sall’s modular spill containment deck.

- High-quality certified steel structure: our bunded flooring is fully constructed with galvanized steel, ensuring the highest strength, durability and long-lasting performances.

- Modular design: the modular design allows for easy installation and best adaptability to every industrial area.

- StawaR compliance: this compliance assure you the highest quality and safety level.

- Watertight tested and welding quality certified: we thoroughly watertight test every sump in compliance with UNI EN ISO 3834:2-2021 standard so that you know you buy the most safe and quality spill containment system.

- Acid-resistant: the interior coating of Sall’s bunded floor is made of anti-acid material such as polyethylene, polypropylene, or PVC, so that you have a drive over steel sump flooring with also the advantages of plastic spill decking systems.

- Hot-dip galvanized self-supporting and heavy load grating: this grid has a thickness of 50mm and allows frequent vehicles transit (forklift, pallet jacks) and is also highly resistant against corrosion.

- Access ramps: bunded floor includes access ramps built for convenient and easy passage of forklifts and other equipment and help reducing the risk of stumbling for people.

Accessories for best bunded floor installation

- Spacers to ensure the ideal distance between modules and to securely fasten them together for a perfect fit.

- Joint elements so that modules can be joined seamlessly leaving no gaps or space among the modules.

- Cross elements to effectively and completely cover the joints between four modules.

- Fastening elements to securely anchor the bunded flooring modules to the ground, thus ensuring stability.

- Galvanized steel access ramps with sump fastening system for the most safe access to the bunded area.

- Corner ramps specifically designed to cover and protect the corners of the bunded flooring system.

- Standard steel ramps.

All the Sall’s steel ramps are intended also for forklift passage and are available in the three above models to meet every industrial needs.